Services

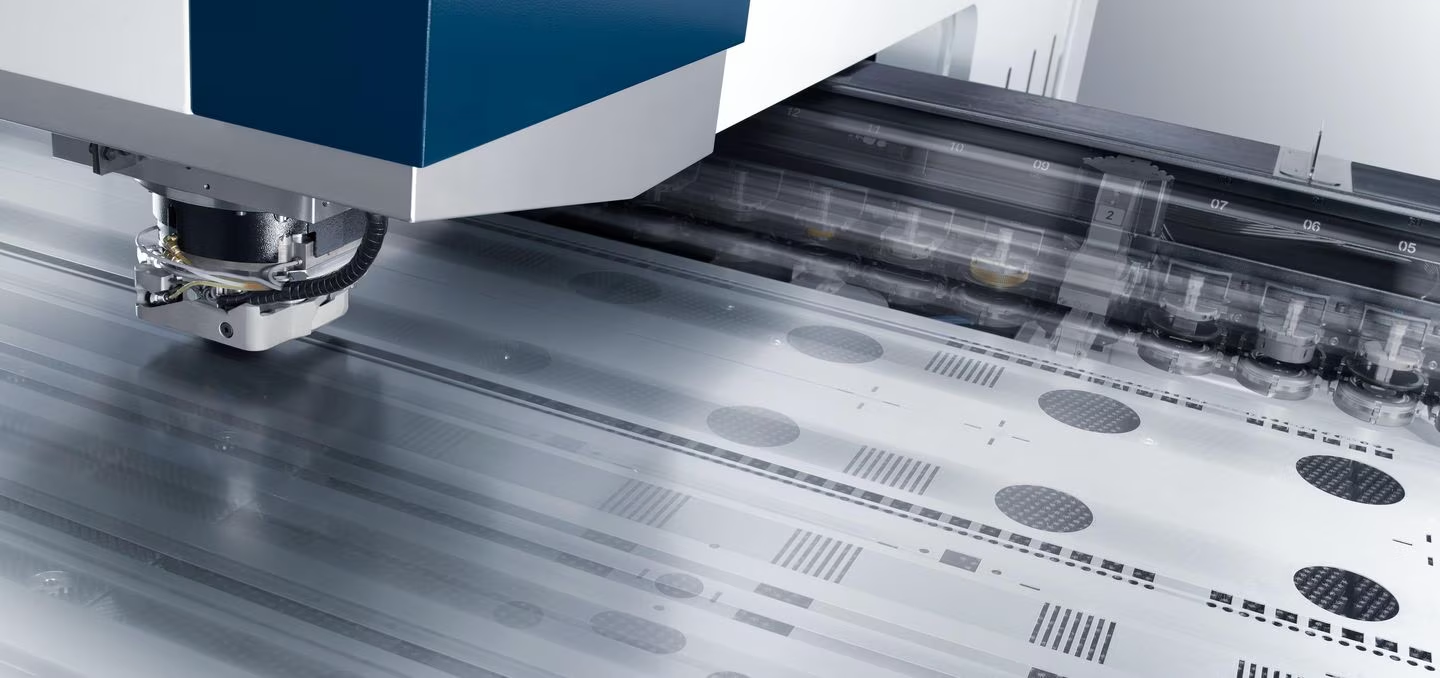

Sheet metal Punching

Sheet Metal Punching is a key process in metal fabrication where holes, slots, or custom shapes are created in sheet metal using a punch press and die. It’s a fast, accurate, and cost-effective method, ideal for high-volume production and complex designs.

Using CNC-controlled machines, sheet metal punching ensures consistency and tight tolerances across large batches. It supports a variety of metals including steel, aluminum, and stainless steel, making it a versatile choice across industries like automotive, electronics, and industrial manufacturing.

Key Benefits:

-

High-speed and precise operation

-

Minimal material waste

-

Supports complex and repeatable patterns

-

Compatible with different metal types and thicknesses

Sheet metal Bending

Sheet Metal Bending is a fundamental fabrication process used to deform metal sheets into specific angles and shapes without cutting or reducing material thickness. This is typically achieved using a press brake, which applies force through a punch and die set.

Bending is crucial in creating components like brackets, enclosures, frames, and panels. The process ensures strong, durable shapes that retain structural integrity—ideal for custom designs and functional parts in industries such as construction, electronics, and machinery.

Key Benefits:

-

Precise and consistent angle formation

-

Supports a wide range of metal types and thicknesses

-

Enables complex part designs

-

Enhances strength and functionality without adding joints

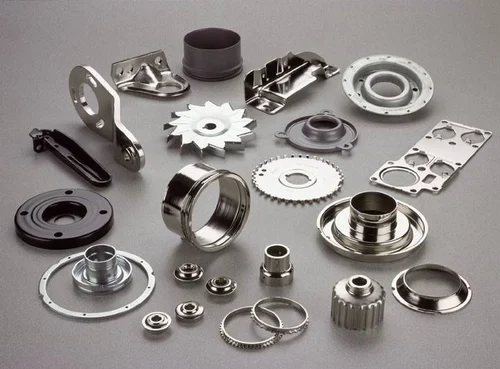

Precision Sheet Metal Components Manufacturing

Precision Sheet Metal Components Manufacturing involves the production of highly accurate and detailed metal parts that meet exact specifications. Using advanced CNC machinery, laser cutting, punching, bending, and finishing techniques, this process ensures tight tolerances and repeatable quality for critical applications.

These components are essential in industries like aerospace, automotive, electronics, and industrial automation—where precision, reliability, and durability are non-negotiable. Every part is manufactured with a focus on accuracy, consistency, and performance.

Key Benefits:

-

Precise and consistent angle formation

-

Supports a wide range of metal types and thicknesses

-

Enables complex part designs

-

Enhances strength and functionality without adding joints

Machines & Infrastructure

Total Units: 3 Units | Total Machines: 8

UNIT I

Unit II

Unit III

Punching(3)

Amada AE2510 NT

Specifications

| AE255NT | AE2510NT | |||

|---|---|---|---|---|

| Press Capacity | kN {ton} | 200 {20} | ||

| Tool Storage | 45/51/58 Stations | |||

| Max. Sheet Size | mm | 1270 x 2500 | ||

| Max Sheet Thickness | mm | 3.2 mm (Brush Table ) 6.4mm (High density brush table) | ||

| Punching Accuracy | mm | ±0.1mm and ±0.07mm (FA mode) | ||

| Hit Rate (25.4mm pitch/3mm stroke) | hpm | X : 400 Y : 290 | X : 390 Y : 300 | X : 380 Y : 280 |

| Max Feed Rate | m/min | X : 80 Y : 60 | ||

TURRET LAYOUT

| Pattern 1 | Pattern 2 | Pattern 3 |

| Layout Pattern | 45st.(4AI) | |

| Maximum tool diameter | E(4-1/2”) | |

| Number of A (1/2”) stations | 24 | |

| Number of B (1-1/4”) stations | 12 | |

| Number of C (2”) stations | 2 | |

| Number of D (3-1/2”) stations | 1 | |

| Number of E (4-1/2”) stations | 2 | |

| Number of G (1-1/4”) stations | 2 | |

| Number of H (2”) stations | 2 | |

Bending

HRB 1003

Specification

| Model | 5020 | 8025 | 1003 | 1303 | 2204 | |

|---|---|---|---|---|---|---|

| Press Capacity | kN {ton} | 500 {50} | 800 {80} | 1000 {100} | 1300 {130} | 2200 {220} |

| Table Length | mm | 2150 | 2600 | 3110 | 3110 | 4300 |

| Frame Gap | mm | 450 | ||||

| Open Height | mm | 520 | ||||

| Stroke Length | mm | 250 | ||||

| MAX Speed | ||||||

| Approach Speed | mm/sec | 150 | 150 | 150 | 150 | 120 |

| Bend Speed | mm/sec | 15 | 15 | 15 | 15 | 12 |

| Return Speed | mm/sec | 150 | 150 | 150 | 150 | 120 |

Trumpf TPP (Turret Punch Process)

Technical Data

TruPunch 1000 (S05) small format | TruPunch 1000 (S05) medium format | |

|---|---|---|

| Dimensions | ||

| Width | 6000 mm 1 | 6550 mm 1 |

| Depth | 7144 mm 1 | 7144 mm 1 |

| Height | 2155 mm 1 | 2155 mm 1 |

| Maximum stroke rate | ||

| Punching (E = 1 mm) | 600 1/min | 600 1/min |

| Marking | 1300 1/min | 1300 1/min |

| Working range | ||

| Punching mode, X axis | 2050 mm | 2500 mm |

| Punching mode, Y axis | 1250 mm | 1250 mm |

| Maximum sheet thickness | 6.4 mm | 6.4 mm |

| Maximum workpiece weight | 150 kg | 150 kg |

| Maximum punching force | 165 kN | 165 kN |

| Tools | ||

| MultiTool tool changing time | 2.4 s | 2.4 s |

| Number of tools/clamps | 15 pieces / 2 pieces | 18 pieces / 2 pieces |

| Part removal | ||

| Maximum part size, part removal flap, punching | 180 mm x 150 mm | 180 mm x 150 mm |

| Maximum part size, part removal flap, punching (with moving table) | 180 mm x 500 mm | 180 mm x 500 mm |

| Maximum part size, fixed chute, punching (with moving table) | 460 mm x 500 mm | 460 mm x 500 mm |

| Consumption values | ||

| Average power input of active auto-shutdown | 0.3 kW | 0.3 kW |

| Average power input in production | 4.3 kW | 4.3 kW |